Toilet paper shortage was a strange side-effect of the Covid19 pandemic. As lockdown was enforced in the US, people resorted to panic buying of toilet paper rolls resulting in several shortage on toilet rolls in leading retail stores. Here are lessons in supply chain learnt from the shortage.

The Product – Toilet Paper

While people in some parts of the world do not use toilet paper, toilet paper is largely considered a necessity across Western societies.

Modern paper goods spread across the globe in the 19th century. In 1857, a New York businessman designed a paper product specifically for lavatory use.

Initially considered a “quack product,” as consumerism rose and indoor flush toilets became the norm, toilet paper became omnipresent (csmonitor, 2020).

Steps in Toilet Paper Supply Chain

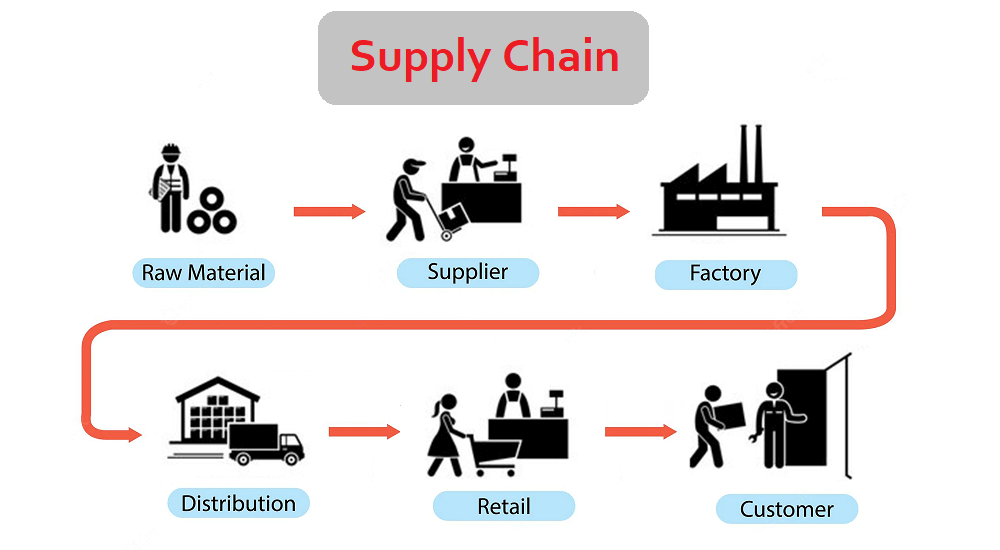

Various steps in the supply chain of toilet paper:

Toilet paper gets raw materials from trees—eucalyptus trees, found mostly in Brazil. Whereas in the U.S. and Canada trees take decades before they can be cut down, the Brazilian trees reach 100 feet in just six or seven years which makes them low cost. The raw materials for toilet rolls are taken from from trees or recycled raw materials.

Toilet Paper Production inlcudes steps like Processing, Pulp milling, Paper Milling.

The finished rolls are then stored in the Warehouse, from where it is distributed to the retailers and reaches the consumers. The disposed toilet rolls are then used for recycling.

Supply of toilet paper is virtually never an issue. It is a commodity that is always in stock. Stores replenish supply on generally stable demand signals and patterns (in a very predictive manner). Paper used for this product is derived from softwood and hardwood trees which is abundant in supply. Majority of toilet paper sold in North America is manufactured in North America. Manufacture of toilet paper is a highly automated process (few employees needed to oversee operations). Most problems with manufacturing are typically resolved very quickly.

The following diagram shows the supply chain of Toilet paper.

Pandemic Causes Shortage of Toilet Rolls

Toilet Paper Supply Chain goes awry during the pandemic. No one predicted the pandemic, and as stay-at-home guidelines were issued, people started stocking up on this essential item.

Industry expects people to buy as much as 40% more toilet paper at home for “occasions” (at workplaces, restaurants, or hotels). But people bought much more during the pandemic. People also tend to hoard things during crisis; many resorted to Panic Buying.

Efficient supply-chains, adoption of “just in time” manufacturing and distribution, means companies don’t have several weeks of supplies sitting around. Not enough stock in inventory (Wieczner, 2020).

Even though production has increased, back orders are likely to take a long time to clear. Persistently empty shelves further adds to the perception that the shortage exists, so panic buying continues and shortage continues. As demand has increased, demand for virgin pulp (raw material) has also increased, impacting the price of the commodity.

Closing Thoughts

Historically, demand for toilet paper has been consistent and so toilet paper seemed to be the perfect model for just-in-time manufacturing. Retailers usually do not stock more as it takes up valuable space (because of its bulk). When the pandemic struck, the existing supply chains were not in a position to scale up much. Manufacturers were reluctant to spend more as toilet paper works on wafer thin margins.

Despite paper machines running at full capacity, overall production in the US increased only 8 percent. Companies were not ready to spend an additional paper machine (costing roughly $300 million) to scale up production. No business wants to be stuck with mounds of rolls when buying will finally slow down. This pandemic exposed the limits of lean supply-chain management.

Some manufacturers are adapting to the situation by producing smaller sized packs, inctead of “mega rolls”, as it minimizes downtime of the machines. Companies like P&G are planning to redesign their operations to adapt to a significantly more volatile environment.

References

csmonitor (2020). Hot commodity: How toilet paper became an icon of stability

New (2010), The Transparent Supply Chain

Oleksy (2020), Supply Chain and Toilet Paper—What You Need to Know.

SupplyChainGameChanger (2020) The Toilet Paper Supply Chain

BATheories.com is managed by a group of educators from Mumbai. We also manage the website StudyMumbai.com. Our panel includes experienced professionals and lecturers with a background in management. BATheories is where we talk about the various business theories and models for BA (Business Administration) students.